£500 excluding VAT. Order up to 1pm for

Next Day DeliverySome items will take 2-5 business days Public Sector

Binding Outlet – One Stop For All Binding Requirements!

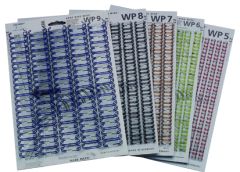

Binding machines and supplies can take many forms. Binding Outlet specialises in wire binding machines, comb binding machines, coil binding machines, laminating machines and binding supplies manufactured by leading manufacturer Renz.

By offering binding solutions specific to your needs, we have developed a great relationship with our customers over the years, as they value our consultative approach. Binding Outlet is a renowned supplier and distributor of the leading binding machine manufacturer – Renz. Browsing through our exceptional range of binding solutions, you will find Binding Outlet, a one-stop solution for all binding machine requirements. By delivering the best products throughout the United Kingdom, we have become one of the most trustworthy distributors.

Latest Blog

-

Posted: March 09, 2021Read more »

If we are not wrong, then you might have faced this situation at least once in your life when you finished your documents after weeks of preparation and hard work, then bind it with for your representation, just to find out that you have made an error. Maybe you missed one or two pages or placed the

-

Posted: September 20, 2019Read more »

If you have binding work daily, then one piece of equipment worth investing your money in is a modular binding punch. A modular punch is a machine that allows you to interchange punching dies for different binding styles. This is implemented with interchangeable die sets so that you can punch the right

-

Posted: September 13, 2019Read more »

One of the best ways to give your documents an ultimate finish and a professional look is binding. It not only provides an elegant look to your documents but also protects them from dust and damage. But what is the best binding method for your documents?

There are a wide variety of binding